Table of Contents

Threaded Flange Manufacturer, Supplier, and Exporter in India

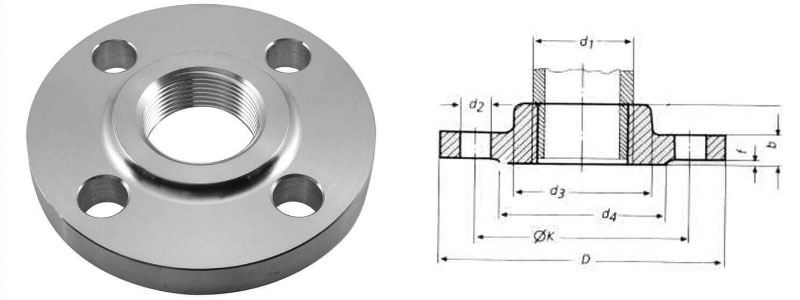

Threaded Flange is manufactured with top-quality materials in different sizes according to the client’s requirements. Viha Steel & Forging is the leading ANSI B16.5 Threaded Flange Supplier, Class 150 Threaded Flanges Manufacturer, Dealer, and Exporter in India. Viha Steel & Forging is an ISO 9001:2015 certified company that has been in existence since 2003. Viha Steel & Forging is known worldwide for its extensive high-quality range of ASME B16.47 Threaded Flange. At Viha Steel & Forging, we have our research center to help gather the required knowledge about the latest technologies and keep increasing the quality of the Threaded Flange with each new research in our research center.

Stockist of Stainless Steel Threaded Flanges, ASME B16.5 Screwed Flanges, Threaded Weld Flange, Global Supplier of Flat Faced Threaded Flanges, Threaded Flanges, ANSI B16.5 Class 150 Threaded Flanges, Threaded Flanges Dealer in India, ANSI B16.5 Threaded Flanges.

Viha Steel & Forging is a specialized manufacturer of high-quality ASME/ANSI/DIN standard Threaded Flanges in India. We offer immediate delivery programs for standard sizes of Stainless steel Threaded Flanges and Carbon steel Threaded Flanges. Threaded Flanges are available with RTJ faces, raised or flat, and are also available in orifice configurations.

Viha Steel & Forging manufactures and provides solely quality tested and difficult ASTM | ASME | ANSI Threaded Flange. ASTM | ASME | ANSI Threaded Flange at Viha Steel & Forging bear hardness and several toughness checks before provisioning it to our purchasers. We have over 99% happy purchasers. We also supply Companion Flange, Orifice Flange, Nipo Flange, etc.

Stainless Steel Threaded Flange

ANSI B16.5 Threaded Flange

Threaded Flange Specification, Grades, Sizes

| ASME B16.5 Threaded Flange Size Chart | 1/2″ (15 NB) to 48″ (1200NB) DN10~DN5000 | ||

|---|---|---|---|

| Threaded Flange Standards | ANSI/ASME B16.5, B16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, GOST Flange, ASME/ANSI B16.5/16.36/16.47A/16.47B, MSS S44, ISO70051, JISB2220, BS1560-3.1, API7S-15, API7S-43, API605, EN1092 | ||

| Threaded Flange Pressure Rating ANSI | Class 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS Threaded Flange | ||

| Threaded Flange Pressure Calculation in DIN | 6Bar 10Bar 16Bar 25Bar 40Bar / PN6 PN10 PN16 PN25 PN40, PN64 Threaded Flange | ||

| JIS | 5K, 10 K, 16 K, 20 K, 30 K, 40 K, 63 K Threaded Flange | ||

| UNI | 6Bar 10Bar 16Bar 25Bar 40Bar Threaded Flange | ||

| EN | 6Bar 10Bar 16Bar 25Bar 40Bar Threaded Flange | ||

| Coating | Oil Black Paint, Anti-rust Paint, Zinc Plated, Yellow Transparent, Cold and Hot Dip Galvanized Threaded Flange | ||

| Most common types of Threaded Flange | Forged / Threaded / Screwed / Plate | ||

| Test Certificates | EN 10204/3.1B Raw Materials Certificate 100% Radiography Test Report Third-Party Inspection Report, etc |

||

| Production technique | Forged, Heat-treated, and machined | ||

| Connect Type/ Flange Face Type | Raised Face (RF), Ring Type Joint (RTJ), Flat Face (FF), Large Male-Female (LMF), Lap-Joint Face (LJF), Small Male-Female (SMF), Small Tongue, Large Tongue & Groove, Groove | ||

| Special design | As per your drawing

AS, ANSI, BS, DIN, and JIS |

||

| Test | Direct-reading Spectrograph, Hydrostatic testing machine, X-ray detector, UI transonic flaw detector, Magnetic particle detector | ||

| Equipment | Press machine, Bending machine, Pushing Machine, electric bevelling machine, Sand-blasting machine, etc | ||

| Manufacturer of | ANSI DIN, GOST, JIS, UNI, BS, AS2129, AWWA, EN, SABS, NFE, etc. Threaded Flange: -BS Flange, EN Flange, API 6A Flange, ANSI Flange, ASME Flange, DIN Flange, EN1092-1 Flange, UNI Flange, JIS/ KS Flange, BS4504 Flange, GB Flange, AWWA C207 Flange, GOST Flange, PSI Flange

|

||

| Grades | |||

| Stainless Steel | ASTM / ASME 201, 202, 301, 304, 304L, 310, 310S, 316L, 316TI, 317, 317L, 321, 347, 409, 409M, 409L, 410, 410S, 420, 430, 431, 441, 444, 446, 17.4PH, 904L | ||

| Super Duplex Steel | S32750 | ||

| Duplex Steel | ASTM / ASME SA 790 UNS NO S 31803 , S 32205 , S 32550 , S 32750 , S 32760. | ||

| Carbon Steel | ASTM / ASME A 335 GRP 1 , P 5 , P 9 , P 11 , P 12 , P 22 , P 23 , P 91 | ||

| Alloys Steel | ASTM / ASME A 691 GRP1 CR , 1 1/4 CR , 2 1/4 CR , 5 CR , 9CR , 91. | ||

| Nickel Alloys | Nickel Alloys 200, Nickel Alloys 201 | ||

| Titanium | Grade 1, Grade 4, Grade 5(Ti 6Al-4V), Grade 6(Ti 5Al-2.5Sn), Grade 7, Grade 11, Grade 12, 8Ai-1Mo-1V, Grade 9(3Al-2.5V), 6Al-6V-25n, 6Al-2Sn-4Zr-2Mo, 6Al-7Nb, Grade 23(Ti 6AL-4V ELI), Grade 5 ELI | ||

| Inconel | Inconel 600, Inconel 601, Inconel 625, Inconel 625LCF, Inconel 686, Inconel 718, Inconel 800, Inconel 825, Inconel X-750 , Inconel 690, Inconel 602, Inconel 617, Inconel 925, Inconel A-289, Inconel AL-6XN, AL-904L | ||

| Hastelloy | Hastelloy C-22, Hastelloy C-276, Hastelloy C-2000, Hastelloy C-4, Hastelloy X, Hastelloy B, Hastelloy N, Hastelloy G | ||

| Molybdenum | ASTM / ASME A 182 GR F 5, F 9 , F 11 , F 12 , F 22 , F 91, ASTM B387, Ferro Molybdenum | ||

| Cobalt | Cobalt HS-6, Cobalt HS-4, Cobalt HS-25, Sterlite Grade 1, Sterlite Grade 6, Sterlite Grade 12, Sterlite Grade 21 | ||

| Niobium | ASTM B394, R04200 R04210 | ||

| Nimonic | Nimonic75, Nimonic80, Nimonic85, Nimonic90, Nimonic263, etc | ||

| Tungsten | W1 WAl1, W61, etc, Carbonide Tungsten, Copper Tungsten, Nickel Tungsten | ||

| Nichrome | Nichrome90, Nichrome80, Nichrome80A, Nichrome RW80, Nichrome75, etc | ||

| Magnesium | Magnesium AL017100, AL017140, AL017150, AL017160, AL017200, AL017210, AL017250, etc. | ||

| Tantalum | Tantalum – Grade 1. | ||

| Monel | Monel 400, Monel k500 | ||

| MU-METAL | MU-METAL | ||

| Zirconium | Zirconium 702, Zirconium 705, Zirconium 705, Zirconium-2, Zirconium-4 | ||

| Beryllium Copper | Alloy 25 UNSC17200 | ||

| Aluminium | 1050,1100, 2017, 7150, 7178, 7575, 2050, 7085, 2011 A92011, 2014A A92014, 2024 A92024, 2219, 5052 A95052, 5083 A95083, 5754, 6061 A96061 A86061, 6063, 6082 A96082, 7071 7020, 7050 A97050, 7075 A97075 A87075, 7175 | ||

| Copper Alloys | C 11000, C 10200, C 12200, C 51100, C 51000, C 51900, C 52000, C 52100, C 74500, C 75700, C 75400, C 76400, C 77000, C 21000, C 22000, C 23000, C 24000, C 26000, C 26800, C 27000, C 27200, C 28000 | ||

Additional Information:

Pay Mode Terms: L/C (Letter of Credit), T/T (Bank Transfer), Other

Port of Dispatch: Mumbai OR KALAMBOLI India

Packaging Details: Threaded Flanges are given marking, painted with black japan or black Board (Mat Finish) & will be packed in a bagging bag with stickers written with size, grade & quantity.

Inconel Threaded Flanges, Stockholder Of DIN86029 PN10 Threaded Flange, Copper Nickel Screwed Flanges Exporter, Best Price of Duplex Steel Screwed Flanges, Hastelloy C22 Threaded Flange, Class 300, 600, 900, 1500 Threaded Flanges Wholesaler, Alloy 20 Threaded Flanges Traders in India

ASME B16.47 Series A and B Flanges, Manufacturer of Threaded Forged Flanges, ASTM A182 Stainless Steel Threaded Flange, Threaded Flange Dimensions, Alloy Steel Threaded Plate Flanges Manufacturer, MSS SP-44 Threaded Flanges in Mumbai, India.

Viha Steel & Forging has created a name in the Indian market as the leading Threaded Flange manufacturer and supplier in India. Viha Steel & Forging has its manufacturing plants in different cities in India. Viha Steel & Forging Orders are guaranteed fast delivery of Threaded Flange in India. The main reason being we have excellent warehousing and storage facilities for both finished and unfinished goods. Besides manufacturing the ANSI B16.5 Threaded Flange, we are well known for supplying, distributing, and exporting the ASME B16.47 Threaded Flanges.

Threaded Flange Application And Uses

- Threaded Flange for Textile Machinery

- ASME B16.9 Threaded Flange for Chemicals Industry

- Threaded for Power Plants Industry

- ANSI B16.5 Threaded Flange for Oil and Gas Processing

- Threaded Flange for Pharmaceuticals Industry

- EN 1092-1 Threaded Flange for Water treatment facilities

- Threaded Flange for Desalination

- PN10 Threaded Flange for Pulp and Paper Industry

- ASME B16.9 Threaded Flange for Construction

- Threaded Forged Flange for Refinery & Petrochemicals

- Threaded Flange for Energy Industries

ANSI ASME B16.5 Class 150lb Threaded Flange Dimensions

| Drilling | ||||||||

|---|---|---|---|---|---|---|---|---|

| Nominal Bore Threaded Flanges | Dia. (D) | Thick. (E) | Dia. (F) | Dia. (B) | Height1(H) | Nbr | Holes | Dia. (C) |

| 1/2″ | 90 | 9.6 | 35.05 | 30 | 14 | 4 | 15.87 | 60.3 |

| 3/4″ | 100 | 11.2 | 42.92 | 38 | 14 | 4 | 15.87 | 69.9 |

| 1″ | 110 | 12.7 | 50.80 | 49 | 16 | 4 | 15.87 | 79.4 |

| 1 1/4″ | 115 | 14.3 | 63.50 | 59 | 19 | 4 | 15.87 | 88.9 |

| 1 1/2″ | 125 | 15.9 | 73.15 | 65 | 21 | 4 | 15.87 | 98.4 |

| 2″ | 150 | 17.5 | 91.94 | 78 | 24 | 4 | 19.05 | 120.7 |

| 2 1/2″ | 180 | 20.7 | 104.65 | 90 | 27 | 4 | 19.05 | 139.7 |

| 3″ | 190 | 22.3 | 127.00 | 108 | 29 | 4 | 19.05 | 152.4 |

| 3 1/2″ | 215 | 22.3 | 139.70 | 122 | 30 | 8 | 19.05 | 177.8 |

| 4″ | 230 | 22.3 | 157.22 | 135 | 32 | 8 | 19.05 | 190.5 |

| 5″ | 255 | 22.3 | 185.67 | 164 | 35 | 8 | 22.22 | 215.9 |

| 6″ | 280 | 23.9 | 215.90 | 192 | 38 | 8 | 22.22 | 241.3 |

| 8″ | 345 | 27.0 | 269.75 | 246 | 43 | 8 | 22.22 | 298.5 |

| 10″ | 405 | 28.6 | 323.85 | 305 | 48 | 12 | 25.40 | 362.0 |

| 12″ | 485 | 30.2 | 381.00 | 365 | 54 | 12 | 25.40 | 431.8 |

| 14″ | 535 | 33.4 | 412.75 | 400 | 56 | 12 | 28.57 | 476.3 |

| 16″ | 595 | 35.0 | 469.90 | 457 | 62 | 16 | 28.57 | 539.8 |

| 18″ | 635 | 38.1 | 533.40 | 505 | 67 | 16 | 31.75 | 577.9 |

| 20″ | 700 | 41.3 | 584.20 | 559 | 71 | 20 | 31.75 | 635.0 |

| 24″ | 815 | 46.1 | 692.15 | 663 | 81 | 20 | 34.92 | 749.3 |

ANSI ASME B16.5 Class 300lb Threaded Flange Dimensions

| Drilling | ||||||||

|---|---|---|---|---|---|---|---|---|

| Nominal Bore Threaded Flanges | Dia. (D) | Thick. (E) | Dia. (F) | Dia. (B) | Height1(H) | Nbr | Holes | Dia. (C) |

| 1/2″ | 90 | 9.6 | 35.05 | 30 | 14 | 4 | 15.87 | 60.3 |

| 3/4″ | 100 | 11.2 | 42.92 | 38 | 14 | 4 | 15.87 | 69.9 |

| 1″ | 110 | 12.7 | 50.80 | 49 | 16 | 4 | 15.87 | 79.4 |

| 1 1/4″ | 115 | 14.3 | 63.50 | 59 | 19 | 4 | 15.87 | 88.9 |

| 1 1/2″ | 125 | 15.9 | 73.15 | 65 | 21 | 4 | 15.87 | 98.4 |

| 2″ | 150 | 17.5 | 91.94 | 78 | 24 | 4 | 19.05 | 120.7 |

| 2 1/2″ | 180 | 20.7 | 104.65 | 90 | 27 | 4 | 19.05 | 139.7 |

| 3″ | 190 | 22.3 | 127.00 | 108 | 29 | 4 | 19.05 | 152.4 |

| 3 1/2″ | 215 | 22.3 | 139.70 | 122 | 30 | 8 | 19.05 | 177.8 |

| 4″ | 230 | 22.3 | 157.22 | 135 | 32 | 8 | 19.05 | 190.5 |

| 5″ | 255 | 22.3 | 185.67 | 164 | 35 | 8 | 22.22 | 215.9 |

| 6″ | 280 | 23.9 | 215.90 | 192 | 38 | 8 | 22.22 | 241.3 |

| 8″ | 345 | 27.0 | 269.75 | 246 | 43 | 8 | 22.22 | 298.5 |

| 10″ | 405 | 28.6 | 323.85 | 305 | 48 | 12 | 25.40 | 362.0 |

| 12″ | 485 | 30.2 | 381.00 | 365 | 54 | 12 | 25.40 | 431.8 |

| 14″ | 535 | 33.4 | 412.75 | 400 | 56 | 12 | 28.57 | 476.3 |

| 16″ | 595 | 35.0 | 469.90 | 457 | 62 | 16 | 28.57 | 539.8 |

| 18″ | 635 | 38.1 | 533.40 | 505 | 67 | 16 | 31.75 | 577.9 |

| 20″ | 700 | 41.3 | 584.20 | 559 | 71 | 20 | 31.75 | 635.0 |

| 24″ | 815 | 46.1 | 692.15 | 663 | 81 | 20 | 34.92 | 749.3 |

ANSI ASME B16.5 Threaded Flange Materials

| Dimensions | Base Material | Pressure Rating |

|---|---|---|

| ASME B16.5 | ASTM A182 (Forgings) ASTM A240 (Plate) | 150#. 300#. 400#. 600#. 900#. 1500#. 2500#. |

| API 605 | ASTM A182 (Forgings) ASTM A240 (Plate) | 150#. 300#. 400#. 600#. 900#. 1500#. 2500#. |

| ASME B16.47series A & B | ASTM A182 (Forgings) ASTM A240 (Plate) | 150#. 300#. 400#. 600#. 900#. 1500#. 2500#. |

| EN1092-1 | ASTM A182 (Forgings) | PN2.5. PN6. PN10. PN16. PN25. PN40. PN63. PN100. PN160. PN250. PN320. PN400. |

| BS4504 | BS970 (Bar)ASTM A240 (Plate) ASTM A182 (Forgings) | PN2.5. PN6. PN10. PN16. PN25. PN40. PN63. PN100. PN160. |

| BS10 | BS970 (Bar)ASTM A240 (Plate) ASTM A182 (Forgings) |

Threaded Flange Related types

- Slip-On Flange Manufacturer in India

- Long Weld Neck Flange Manufacturer in India

- Weld Neck Flange Manufacturer in India

- Socket Weld Flange Manufacturer in India

- Blind Flange Manufacturer in India

- Lap Joint Flange Manufacturer in India

- Threaded Flange Manufacturer in India

- Companion Flange Manufacturer in India

- Orifice Flange Manufacturer in India

- Nipo Flanges Manufacturer in India

- JIS Standard Flange Manufacturer in India

- API 6A Flanges Manufacturer in India

- API Flanges Manufacturer in India

- Square Flange Manufacturer in India

- Expander Flange Manufacturer in India

- Ring Type Joint Flange Manufacturer in India

- Loose Flange Manufacturer in India

- Latro Flanges Manufacturer in India

- Reducing Flanges Manufacturer in India

- Swivel Ring Flanges Manufacturer in India

Client Report

| Threaded Flange Supply in Oil Plant | Rajasthan |

| ASME B16.5 Threaded Flange supply | Gujarat |

| PN10 Threaded Flange | Pune, Maharashtra |

| Threaded Pipe Flanges Supply | Vijaywada, Hyderabad |

Type of Threaded Flange we produce

| Class 150 Threaded Flange | Threaded Threaded Flange |

| Class 300 Threaded Flange | With 1/2 Npt Threaded Flange |

| Class 1500 Threaded Flange | With Threaded Hole Threaded Flange |

| Class 600 Threaded Flange | Weight 150# |

| Class 900 Threaded Flange | Rtj 1500 |

| Class 2500 Threaded Flange | Ring Type Joint |

| Pn16 Threaded Flange | Flat Face Threaded Flange |

| Pn10 Threaded Flange | Flange |

| Pn40 Threaded Flange | Rtj 900 |

| Pn 160 Threaded Flange | Rtj |

| Pn 64 Threaded Flange | Npt |

| Dn150 Pn16 Threaded Flange | Jis 5k |

| Din 2527 Threaded Flange | Jis B2220 |

| Din En 1092-1 Threaded Flange | Jis 10k |

| Din 2633 Threaded Flange | Kf |

| Din 2576 Threaded Flange | B16.47 |

| ASME B16.5 Class 300 Threaded Flange | Ansi B16.5 150 Threaded |

Threaded Flange Manufacturers Suppliers

Our purchaser’s satisfaction depends on various things like quality, Hardness, Delivery Time, Toughness, and our Services for Slip On Pipe Flanges. Viha Steel & Forging may be an Indian supplier of ANSI B16.47 Threaded Flange in INDIA. Our prime quality of DN200 Threaded Flange, sensible client service, and in-house Threaded Flange processing capabilities have made us one of the emerging and leading suppliers for Threaded Flange in India.

- Bengaluru

- Mumbai

- Chennai

- Hyderabad

- Kolkata

- Pune

- Peenya

- Pimpri-Chinchwad

- Channapatna

- Kharagpur

- Nashik

- Bareilly

- Thane

- New Delhi

- Ahmedabad

- Jaipur

- Surat

- Salem

- Gandhinagar

- Varanasi

- Haldia

- Rourkela

- Bangalore

- Moradabad

- Indore

- Bhopal

- Bhiwandi

- Tiruppur

- Sivakasi

- Jamnagar

- Thiruvananthapuram

- Rajahmundry

- Visakhapatnam

- Trivandrum

- Pithampur

- Dibrugarh

- Angul

- Gwalior

- Bhubaneswar

- Vijaywada

- Firozabad

- Bokaro Steel City

- Rajkot

- Bharuch

- Coimbatore

- Kannur

- Nagpur

- Vadodara

- Rudrapur

- Noida

- Panna

- Raipur

- Cochin

- Ludhiana

- Panipat

- Durgapur

- Agra

- Bhagalpur

- Jamshedpur

- Bhilai

- Lucknow

- Kanpur

The Countries We Export Threaded Flange To:

Product dependability and performance have created Viha Steel & Forging leading businessperson, manufacturer, and supplier of Threaded Flanges in India. Every month we tend to export EN 1092-1 Threaded Flange products to India port around four-five containers to completely different customers. Our product Stainless Steel Threaded Flange area unit, is frequently exported to over fifty-five countries. Over the last Nine Years, we tend to have equipped over 2500+ plenty of Threaded Flange to India.

- Saudi Arabia

- Oman

- Kuwait

- Netherlands

- Iran

- Bahrain

- Qatar

- UAE

- Africa

- China

- Nigeria

- Mexico

- Canada

- Venezuela

- United Kingdom

- United States

- South Africa

- Malaysia

- Bangladesh

- Turkey

- Singapore

- Sri Lanka

- Australia

- Brazil

- threaded flange class 150

- threaded flange class 300

- threaded flange connection

- threaded flange dimensions

- threaded flange fittings

- threaded Flange manufacturers in delhi

- threaded flange manufacturers in india

- threaded Flange manufacturers in mumbai

- threaded flange specification

- threaded flange standard

- threaded Flanges exporter in india

- threaded Flanges manufacturer in ahmedabad

- threaded Flanges manufacturer in bangalore

- threaded Flanges manufacturer in hyderabad

- threaded Flanges manufacturer in rajkot

- threaded Flanges stockists in india

- threaded Flanges suppliers in gujarat

- threaded Flanges suppliers in india

- threaded weld neck flange